Are Stringy Spokes Faster? A deep-dive into polymer spokes on road bikes.

Joe Whittingham2025-04-11T02:24:51+00:00String (Polymer) spokes are nothing new. BERD have been using Dyneema fiber in their spokes on mountain bike wheels since 2015. The main advantages are lightweight and vibration damping. However, such spokes have never really taken off amongst road cyclists who traditionally were obsessed with stiffness. However, with more and more roadies running wider tires at lower pressures… and reportedly going faster because of it, does this mean that polymer spokes could be faster? Let’s dive down the rabbit hole.

Trends to Wider Tires

In recent years, hobbyists and pro cyclists alike are moving to wider and wider tires. Not only for comfort, but also apparent speed increases. However, basic science says that a larger tire at lower pressure should have a higher rolling resistance. According to bicyclerollingresistance.com - a Continental GP5000 S TR in 28mm has over 30% more rolling resistance at 54psi compared to 108psi… but in real-world testing many people are getting faster results at lower tire pressures.

I think the answer lies in vibration losses. When you’re riding a bicycle, even on fairly smooth roads, there are vibrations travelling through the tires, wheels, frame, seatpost and into your body. Vibrations are simply very small accelerations at very high frequencies. Newton’s first law of motion tells us that nothing will accelerate unless a force is applied and the first law of thermodynamics states that the energy to create those accelerations can’t simply be created out of thin air. As the only thing powering the bike is the rider, that means the energy to cause those vibrations is ultimately coming from you; in theory robbing you of your speed. This would explain why in the real world many people report riding faster for the same power when using lower pressures or wider tires.

Suspension of a Road Bike

One of the main reasons why tire pressure changes make such large differences to the feeling and performance of a road bike is because the tires make up the majority of the suspension of the bike. Especially on stiff, carbon fiber race bikes. This means small changes to other components also have the potential to have large effects on the overall suspension and vibration damping of the bike.

Stringy spokes on Mountain Bikes

Mountain bikers have long been singing the praises of string spokes. At the Olympics last year (where athletes’ equipment decisions are usually less influenced by team sponsors) both the men and women’s cross country mountain bike gold medals were won by riders on BERD polymer spokes, so there’s clearly something in it. However, there has never really been much adoption of polymer spokes to the road bike market. BERD have a range of road bike wheels using the spokes, but they don’t seem to be particularly popular. I suspect the reason for this is a conception that polymer spokes aren’t aero… but more on that later.

The Carbon Spoke revolution

If all of this sounds familiar… it should. This is a similar story to the carbon spoke revolution of a few years ago. At the time, carbon spokes weren’t new. The likes of lightweight and madfiber had been making wheels with carbon spokes for years. But they never really became a mainstream product and one of the reasons was the interaction between the spoke and the rest of the wheel. Before STREN made the popular ST-01, there wasn’t really a reliable way to lace carbon spokes to a hub or a rim. The ST-01 design was probably first used on the CADEX wheels, but later adopted to much success by many of the Chinese brands.

The Ti-Fi Revolution?

This is similar to the situation we find ourselves in today, however, GOOSYNN claims to have a solution. Their Ti-Fi polymer spokes feature a mechanical interface with titanium fixtures on both ends of the spoke. BERD’s own patented approach is to use the weave of the polymer (and some fancy adhesive) to grip onto a stainless steel insert in a similar way to a Chinese finger trap. The harder the spoke is pulled, the tighter the grip on the steel insert. However, one limit of this method is that the surface area between the weave and insert has to be quite large, meaning the size (and therefore weight) of the steel insert is not insignificant. BERD claims to have the lightest spokes in the world at 2.5g for its spokes, however the GOOSYNN spokes take that a step further weighing in at 2.2g per spoke and therefore taking BERD’s crown as the lightest spoke in the world. Another advantage of having titanium fixing on each end is that the spokes can be built into any carbon-spoke compatible hub and laced to any regular rim. The patented mechanical interface is designed to be robust and minimize spoke stretching. Other polymer spokes may have to be threaded through themselves at the hub flange, putting stresses on the hub flange that they may not have been designed to take. With GOOSYNN’s Ti-Fi solution, the forces are distributed through the hub flange exactly how they would be with a carbon spoke. Oh, and if you’re wondering, Ti-Fi comes from Titanium Polymer Fiber… so now you know.

What makes polymer spokes so special?

The most obvious thing is the weight. Carbon spokes got lots of their fame from being lighter than steel spokes, however, polymer spokes are lighter than both. A GOOSYNN spoke weighs in at just 2.2g per spoke. For reference the most common carbon spoke, the ST-01 is around 2.6g and a steel spoke such as a CX-Ray about 4.1g. That means on a 40 spoke wheelset, you’re saving about 20g over carbon spokes and 75g over steel spokes.

But that’s not the main selling point of the GOOSYNN spokes. The main difference between steel and carbon spokes is the deformation of the spoke. For a given force, the Ti-FI spokes will deform a lot more than carbon and steel spokes.

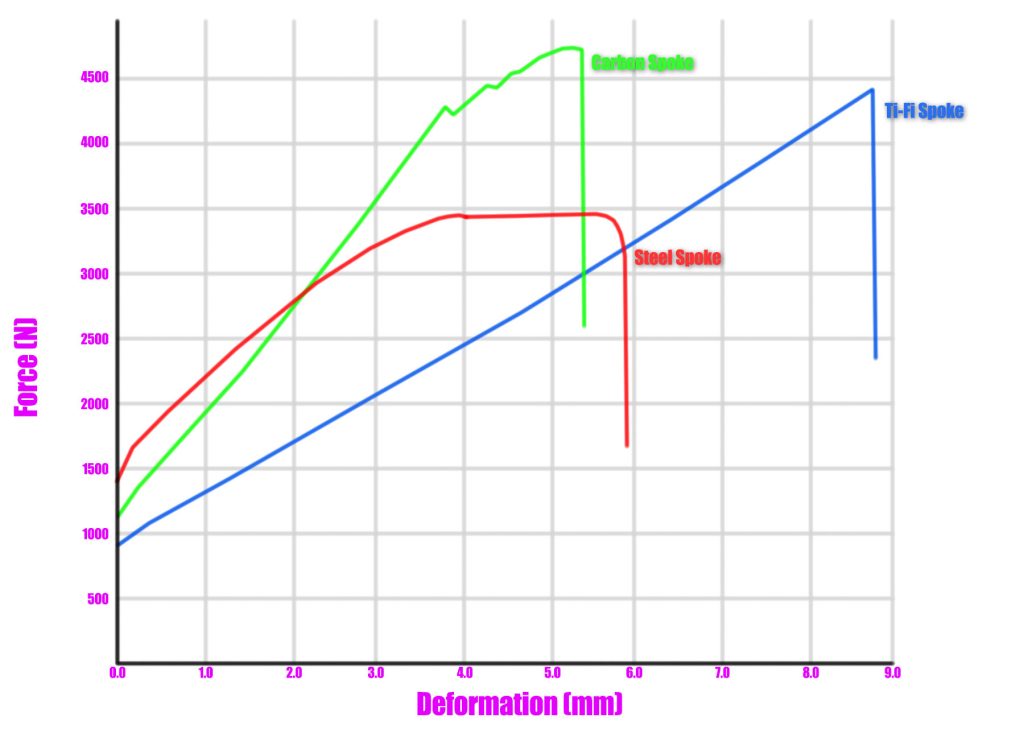

The above chart shows the elongation of 3 spokes at different loads. There are a few things we can learn from this graph. First; the failure load of the spoke. The steel spoke fails at around 3500 Newtons (or 350kgf). Next the Ti-Fi outperforms the steel spoke to fail at just short of 4500 Newtons. The carbon spoke has the highest tensile strength finally failing at over 4500 Newtons.

However the most interesting observation is the deformation per newton, represented by the steepness of the curves. The steeper the curve, the less elastic the material.

At the spokes usual working loads, we get the following results:

Carbon Spoke | 800 N/mm |

Steel Spoke | 580 N/mm |

Ti-Fi Spoke | 380 N/mm |

If we take the steel spoke as the norm. The TiFi spoke has 35% more deformation and the carbon spoke has 38% less. From this we can hypothesize that a TiFi spoked wheel will have the opposite advantages and disadvantages of a carbon spoked wheel when compared to a regular steel spoked wheel.

I was unable to think of a suitable experiment to measure the vibration damping properties of an individual spoke (although later I’ll show you for the entire wheelset). However, BERD claims “…200% better vibration damping…” compared to steel spokes. If I had to guesstimate, I would guess that the TiFi spokes have even more damping, as for a given spoke length the TiFi spokes have a longer pure polymer cross-section than the BERD spokes. The steel insert in the BERD spoke is quite long and that section of the spoke presumably acts similar to a steel spoke. However, this is just my theory, so take it with a grain of salt.

What about the Wheelset?

Now we’ve analyzed the spokes themselves, we can see what happens when you build them into wheelsets. As mentioned before the GOOSYNN Ti-Fi spokes are compatible with carbon spoke hubs. Therefore I asked GOOSYNN to lace up 2 identical pairs of wheels with the same rims and same hubs with the only difference being the spoke material. This will allow us to make apples to apples comparisons between the two. For a steel spoke wheelset I chose an industry-leading high performance steel spoked wheelset; The Roval Rapide CLX II. The spoke count, rim shape and hub design are all significantly different to the 2 GOOSYNN wheels which will make comparisons more difficult.

Weight

|  |  |

Goosynn TiFi wheels weighing in at 1200.0g | Goosynn Carbon Spoke wheels weigh 1261.0g | I’ve weighed my Rovals before at 1521.5g |

Although the weight difference between each spoke are minor, with so many spokes the difference adds up. The TiFi spokes are the lightest, around 5% lighter than the carbon spoked wheels and around 20% lighter than the steel spoked wheels.

Stiffness

With more elastic spokes, the wheelset should be less stiff. Is that a good or a bad thing, let’s talk about the three main stiffness components of a wheelset.

Lateral Stiffness

This is the stiffness of the wheel when the rim is pushed parallel to the wheel axle. Lateral stiffness has a big effect on how the wheels feel when riding at low cadence out of the saddle and also handling characteristics. It’s also one of the easiest to measure. We took 12 measurements per wheelset and obtained the following results:

Wheel | Lateral Stiffness |

Carbon Spoked GOOSYNN | Front: 42.7 N/mm Rear: 39.3 N/mm Average: 41.0 N/mm |

Steel Spoked Roval | Front: 43.3 N/mm Rear: 69.2 N/mm Average: 56.3 Nmm |

Ti-Fi Spoked GOOSYNN | Front: 28.5 N/mm Rear: 25.1 N/mm Average: 26.8 N/mm |

No surprise that the Ti-Fi spoked wheels were the least stiff. What was rather surprising however was the stiffness of the steel spoked Roval wheels. However, the Roval has 24 spokes on the rear wheel compared to GOOSYNN’s 20, giving it a huge bump in stiffness.

In practice how does it feel? When you’re out of the saddle on a steep climb at low cadence, you can feel the lack of stiffness. Is that affecting your performance; it’s hard to say. If you’re running very tight clearance between your tires and your chain / seat-stays, there is the possibility for rubbing. In our testing, an 87kg rider rode the wheels up steep climbs with 4mm of clearance around the seat stays and experienced zero rubbing.

Torsional Stiffness

Torsional stiffness is the ability of the wheel to transfer torsional forces (ie: drive / pedalling forces and braking forces.)

My current setup has no way to measure torsional stiffness, but we can hypothesize that the results are similar to the lateral stiffness results.

Higher torsional stiffness will result in a more snappy acceleration feeling when stamping hard on the pedals. Anyone who has ridden carbon spokes can attest to this. However higher torsional stiffness also has its disadvantages. As Humans, our pedalling stroke is very uneven. We apply most of the power when the pedals are at the 3 and 9 o’clock positions. When our feet are at the 12 o’clock and 6 o’clock positions, we have much less power. A wheelset with low torsional stiffness will act like a spring. During the power phase of the pedal stroke, the spring will compress and then some of this energy will be returned as the spring uncompresses to push you through the ‘dead spot’ of the pedal stroke. Many riders report not liking carbon spoke wheels for high-power TT efforts on the flats for this reason. They describe “not being able to get on top of the gear.” usually because they’re used to steel spokes acting like a spring to help them through the dead spot. Polymer spokes take this further. The whole wheel acts as a spring to help you through the dead spot of the pedal stroke and give a very pleasant, smooth pedalling sensation. However, no system is 100% energy efficient. There is energy being lost in the constant “compressing” and “releasing” of the spring. What % of that energy is being lost is unknown, but it’s not nothing. Having some torsional flex to the wheel can also improve braking performance for some riders helping to ‘smooth out’ the transition from not braking to braking. In wet time trial races you’ll see many riders crash when they hit the brakes for a corner. This is partly because TT disc wheels are overly stiff.

Vertical Stiffness

Vertical stiffness described the ability of the hub to move up and down independent of the rim when mounted on the bike. This is the kind of stiffness that helps to absorb bumps in the road. In an ideal world, vertical stiffness would be low, and lateral stiffness high, however it’s very hard to raise one without raising the other, and vice versa. (Spoke angle and lacing pattern can help.) This means that a laterally stiff wheel feels great when sprinting, etc, but you’ll probably also have a lot of vertical stiffness, leading to more road vibrations being transferred into the bike and into the rider. We’ll cover this in our next section.

Comfort

The greatest advantage of Polymer spoked wheels is the comfort. The vertical compliance of the wheel acts as a suspension to even out small imperfections in the road surface. While the “suspension travel” of the system isn’t huge (a few mm at most) as a percentage of the total suspension of a road bike; it’s quite a lot. This is where I see the biggest potential for Polymer spoked wheels on road bikes. One aspect of this is rider fatigue. If the ride is more comfortable, the rider will experience less fatigue and be able to ride further or longer due to the damping characteristics of the wheels. I was able to quantify these damping characteristics and will talk about them in the next section.

Is Smoother Faster?

This brings us on to perhaps one of the most important sections of this research. Is smoother faster? We already know that many independent studies have found wider tires at lower pressures to be faster due to the ‘smoother’ ride it delivers. Here, we’re not talking about rider fatigue (or lack thereof), we’re simply talking about less energy being wasted through tiny vibrations. Therefore, if we can lessen vibrations we can lessen energy lost and result in more speed. Alternatively, we can run higher tire pressures (for lower rolling resistance) and still maintain the same comfort. That’s the theory, lets see how it pans out:

The Methodology

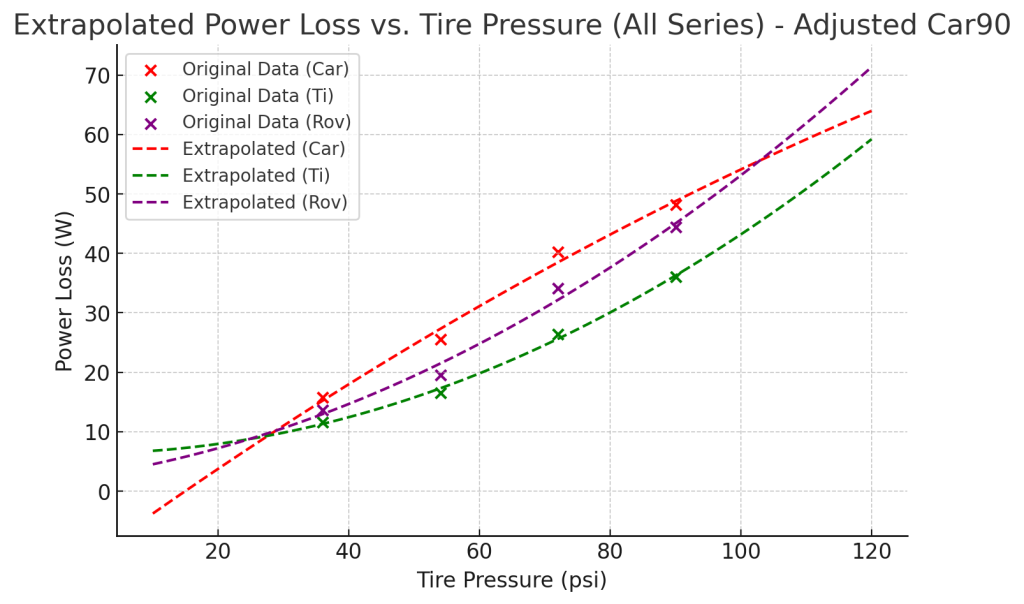

The first step was to measure the differences between different spoke materials. I set all 3 wheelsets up with brand new Continental GP 5000 ST R in 28mm. I even measured the amount of sealant in each tire to keep everything controlled. A high precision accelerometer (ie: an old smartphone) was taped to the top tube of the bike to measure vibrations. I ran each wheelset on the same course at the same speeds. The course was a ~1km loop on a chipseal road surface featuring manhole covers and painted white lines. A very “real world” test. Each tire was ran at 4 different tire pressures; 36, 54, 72 and 90 PSI. I then used the data from the accelerometer to calculate the RMS vibrations going through the bike frame. We can then use RMS, mass and velocity to roughly estimate the power losses using this formula:

The Results

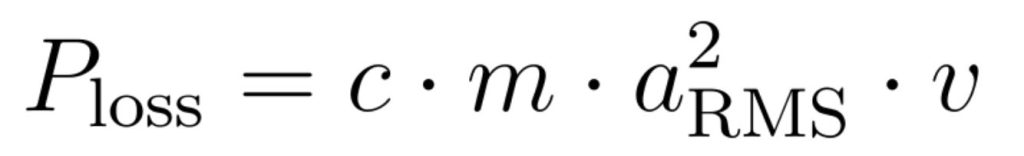

This gives us the following data:

Note the power loss values on the left are orders of magnitude high. This is because the formula assumes the whole mass of the bike + rider is vibrating at the same speed and amplitude as the top tube of the frame. In reality the vibrations felt by the rider are a fraction of those felt by the frame however the relative nature of the power loss will still be accurate.

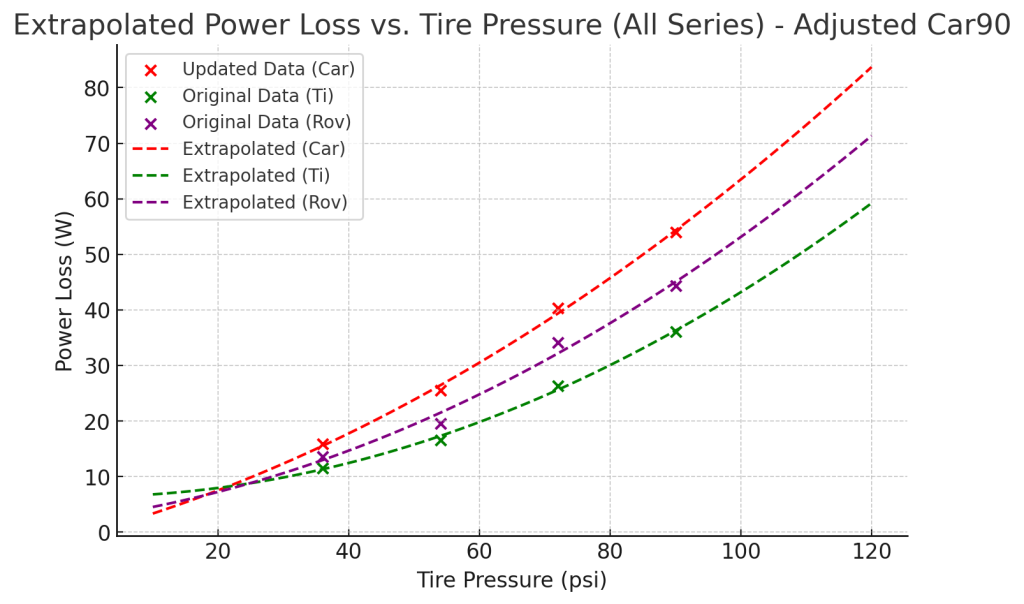

For the labels on the X axis. Car = Carbon spokes. Rov = Steel spokes. Ti = Ti-Fi Spokes. The number following is the air pressure in the tire.

The most obvious observation is the effect of tire pressure on vibration power losses. This is exactly what we’d expect with higher pressures causing higher power loss through added vibrations.

We can also see that regardless of the tire pressure, the 3 spoke materials always have the same effect on vibration power loss. Carbon spokes experience the most, steel spokes experience some, and the Ti-Fi spokes experience the least power loss.

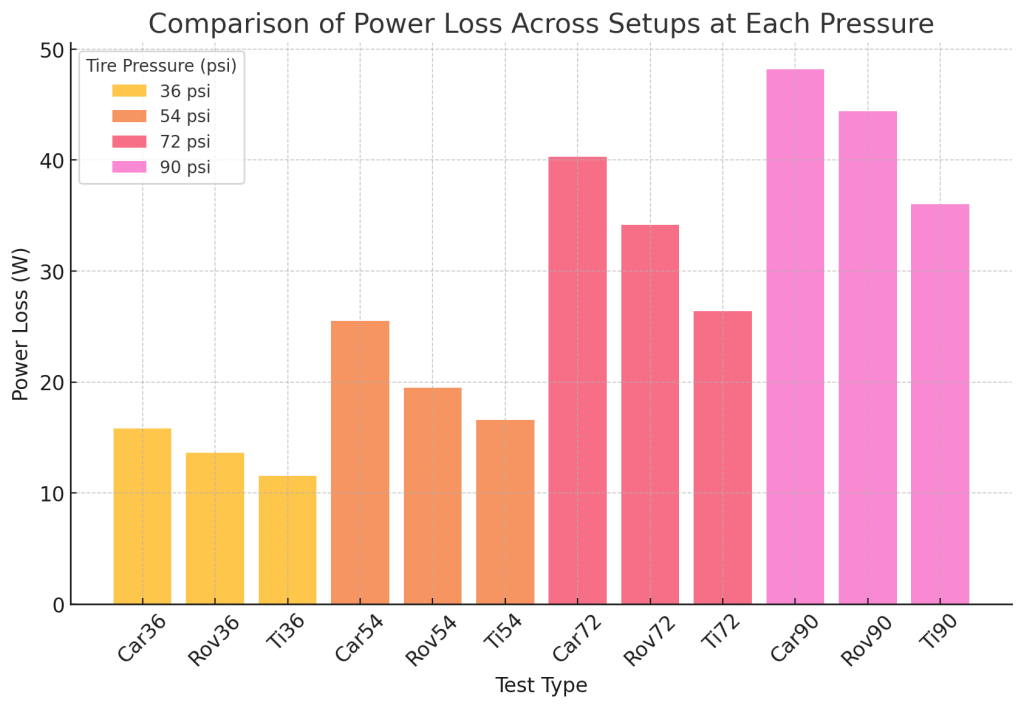

Plotting these values onto a line chart gives us this:

This looked a bit off to me. So I manually adjusted one reading for the carbon spokes at 90psi. It seemed a little low. Maybe there was less PSI in the tire than there should have been. Who knows. But after adjusting the one reading, the graph looks like this:

This shows the relationship between tire pressure and power loss for all three wheelsets. You can use this chart to see roughly “If I run X psi on steel spokes, what psi can I run on TiFi spokes for the same ride feel.”

On average, compared to the steel spokes, you can run the TiFi spokes at 15% higher pressure to get the same ride feel. That equates to about 7-8 PSI. Even at the 25kph test speed, this equates to around a 0.6-0.8 watt saving of rolling resistance.

Compared to carbon spokes the difference is roughly double. You can run the wheels at roughly 20 PSI less for the same amount of vibrations. This equates to around 1.5 watts of rolling resistance saving at 25kph.

But are these rolling resistance savings greater than the vibration loss? Or is there any aerodynamic loss related to the TiFi spokes? We can investigate with some real world testing.

Real-world (aero) testing

To see if any of these findings translate to the real world we decided to test all three wheels. In the real world losses are a combination of aero drag, tire rolling resistance and vibration (damping.) The proportion of each varies with a multiple of variables from rider weight to rider speed.

Testing Methodology

Due to time constraints, we performed all testing at a single tire pressure, 72psi. We conducted tests at two power outputs. One low-speed test at 50 watts. This was to put the emphasis on rolling resistance and vibration losses. The second test was performed at 175 watts. This was in order to amplify the aero performance of the wheels. Having two riders ride simultaneously mitigated the effect of changing weather conditions. At any given time two wheels were being tested so any favourable conditions would affect two wheelsets which would then be re-tested by the other rider later thus minimizing (but not removing) the chance of weather affecting the results. The course was a 1km loop with a very smooth asphalt surface. A rougher surface would no doubt have given more advantage to the TiFi spokes, however finding suitable testing grounds is difficult.

Each run was done for 5 laps (just over 5 kilometers) meaning even distribution of headwind and tailwind. Riders were in adjacent lanes in the event they had to overtake each other, however the tests were started with riders half a lap apart from each other to minimize any affect of drafting. Due to using different lanes, rider “Tom” had a shorter lap on the inside lane and thus faster lap times. All wheels were using the same GP 5000 S TR 28mm tires at 72psi.

Real-World Testing Results

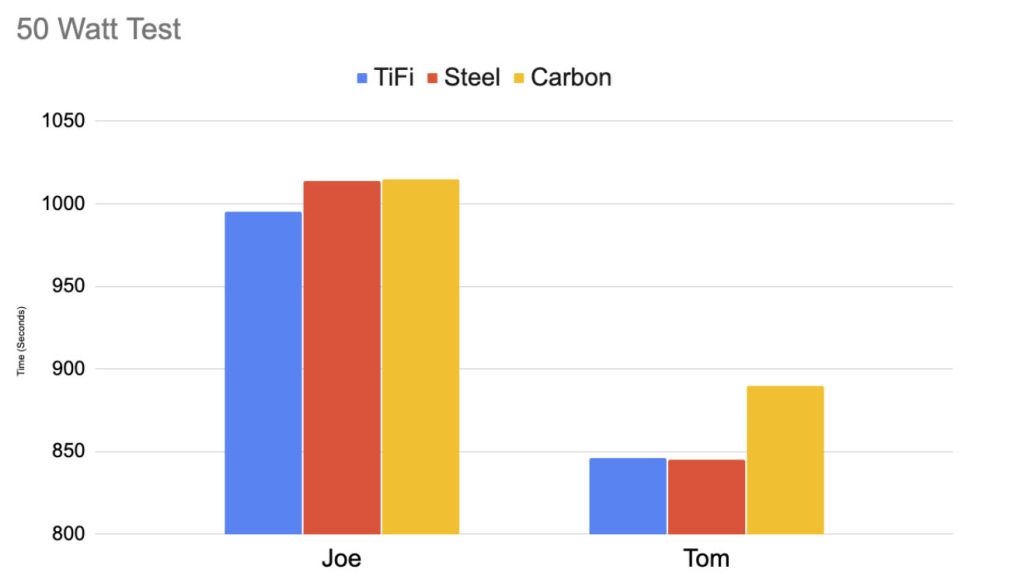

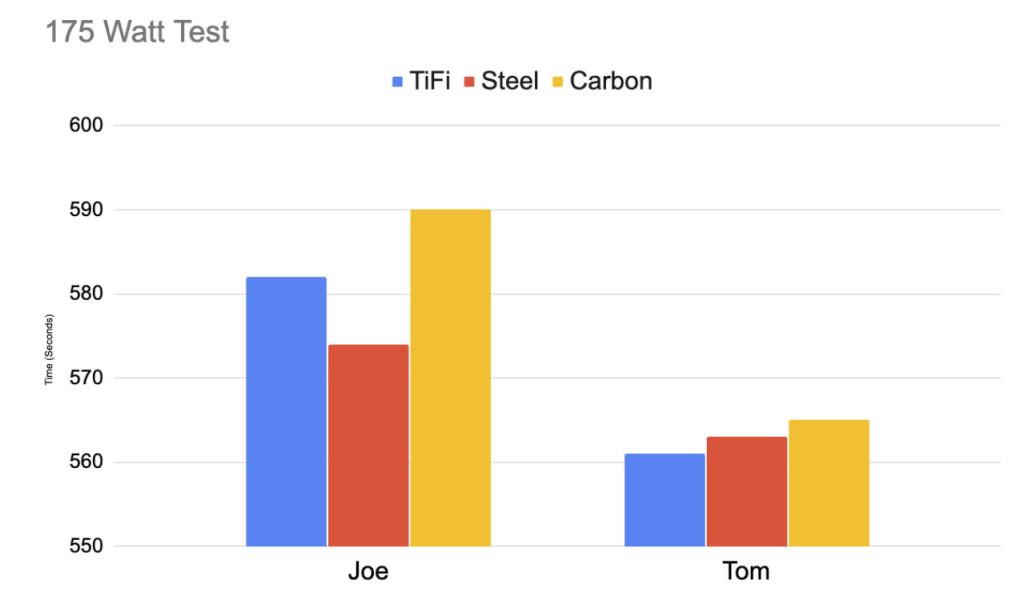

The above are the times for the 50-watt test. Joe had an obvious performance advantage with the TiFi spokes. Rider Tom seemed to have a performance advantage with both the TiFi and Steel spokes.

In the higher speed tests. The results were equally varied. Tom’s results seem a lot more realistic. For whatever reason, in Joe’s testing the steel Rovals overperformed. If the steel spoked wheels were somewhere the TiFi and the Carbon tests we could call it a day and have our conclusion. But it’s never that easy. For the discrepancies between results there could be a multitude of reasons. Joe uses an unpadded bare carbon saddle which may transmit more vibrations to the rider and result in more vibration losses at low speed. Joe is a much smaller rider than Tom making equipment aero drag a larger chunk of the overall drag than Tom’s. Every rider is different and the sweet spot for every rider in terms of aero drag vs rolling resistance vs vibration losses will be different.

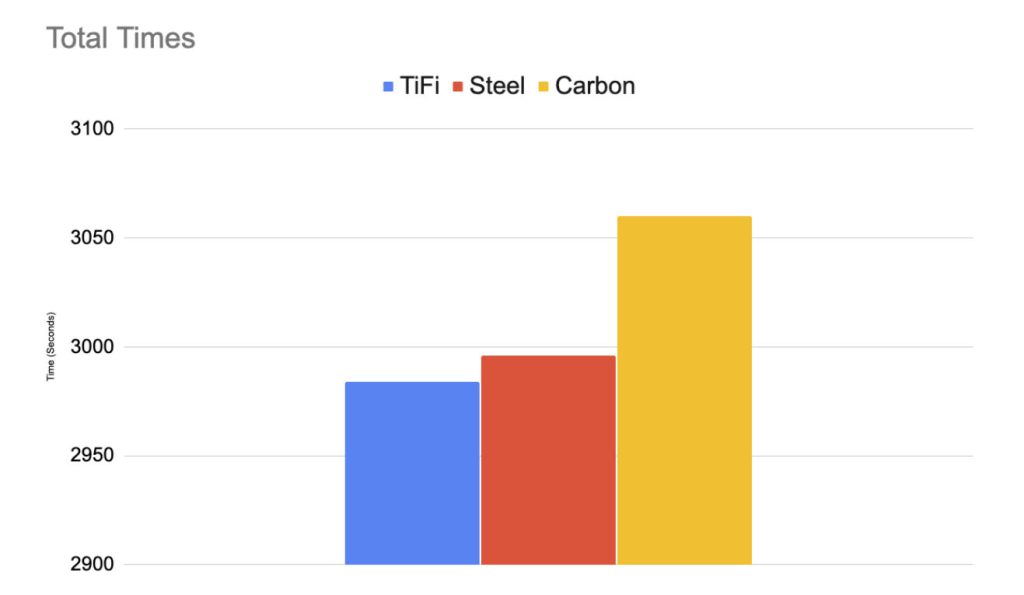

However, we can take advantage of the law of large numbers. If we add up all the data from every test, the effect of small anomalies becomes less. These results represent over two and a half hours of testing of the wheels and therefore a more accurate representation of performance. When we add the total times up, The TiFi are the fastest, however, they’re just 12 seconds faster than the steel spoked Rovals. That represents about 0.5%. Given that most power meters have an accuracy of 1%, we’re well within the margin of error for the test.

Conclusion

While this deep dive may have left us with more questions than answers, there are a few take-aways.

I can say with a high-degree of confidence:

- For a given tire pressure, TiFi spokes transmit less vibrations into the bike frame and therefore offer more comfort.

- Vibrations of the bike and rider are slowing riders down.

- Increasing tire size or lowering tire pressure to add comfort results in higher rolling resistance. (excluding vibrations)

- The Ti-Fi spokes are some of the lightest spokes on the market.

I can say with a lower degree of confidence:

- Everything else being even: A smoother ride is faster.

- The aero penalty of polymer spokes is not obvious in real-world testing.

More testing is needed to validate the findings, especially with regards to speed / aero testing. However, at the very least it seems you can ride these wheels at the same pressure you’re used to and enjoy added comfort without sacrificing speed while simultaneously dropping weight too.

The Goosynn TiFi Range

Author

Founder and CEO of Panda Podium. British expat living in China for 15 years. Love anything with wheels that goes fast. Mainly ride rim brake road bikes, but will generally ride anything - variety is the spice of life.

Leave a Reply

You must be logged in to post a comment.